Explore how custom advanced ceramic solutions are transforming industries — from electronics to energy.

Zirconia Ceramic Degradation Mechanisms

Unexpected surface roughening and strength loss can arrive quietly; consequently, unrecognized degradation triggers microcracking, performance drift, and premature fracture in zirconia ceramic components. Zirconia ceramic

Zirconia Ceramic Strength Explained Through Engineering Performance Data

High mechanical loads, brittle failure risks, and long-term reliability often limit material choices in demanding engineering systems. Consequently, zirconia ceramic strength attracts attention where conventional

Zirconia Ceramic Properties in Technical Materials Systems

High-performance ceramics frequently fail when property assumptions oversimplify real conditions; consequently, zirconia ceramics demand a precise property-level understanding to avoid structural, thermal, or chemical misapplication.

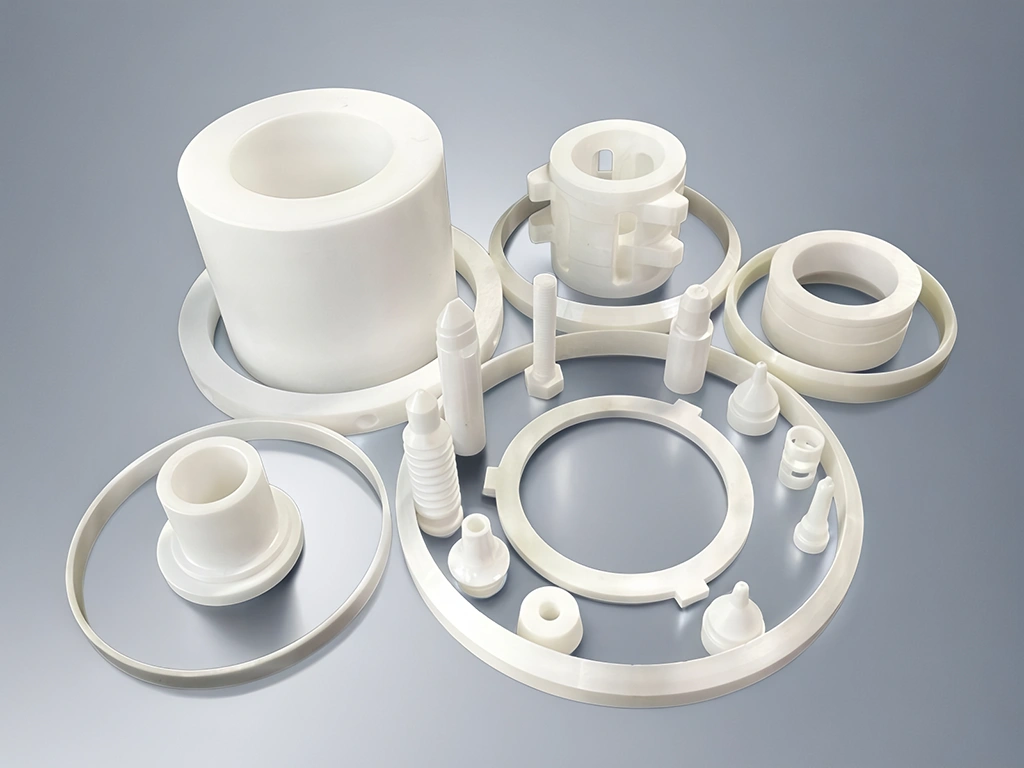

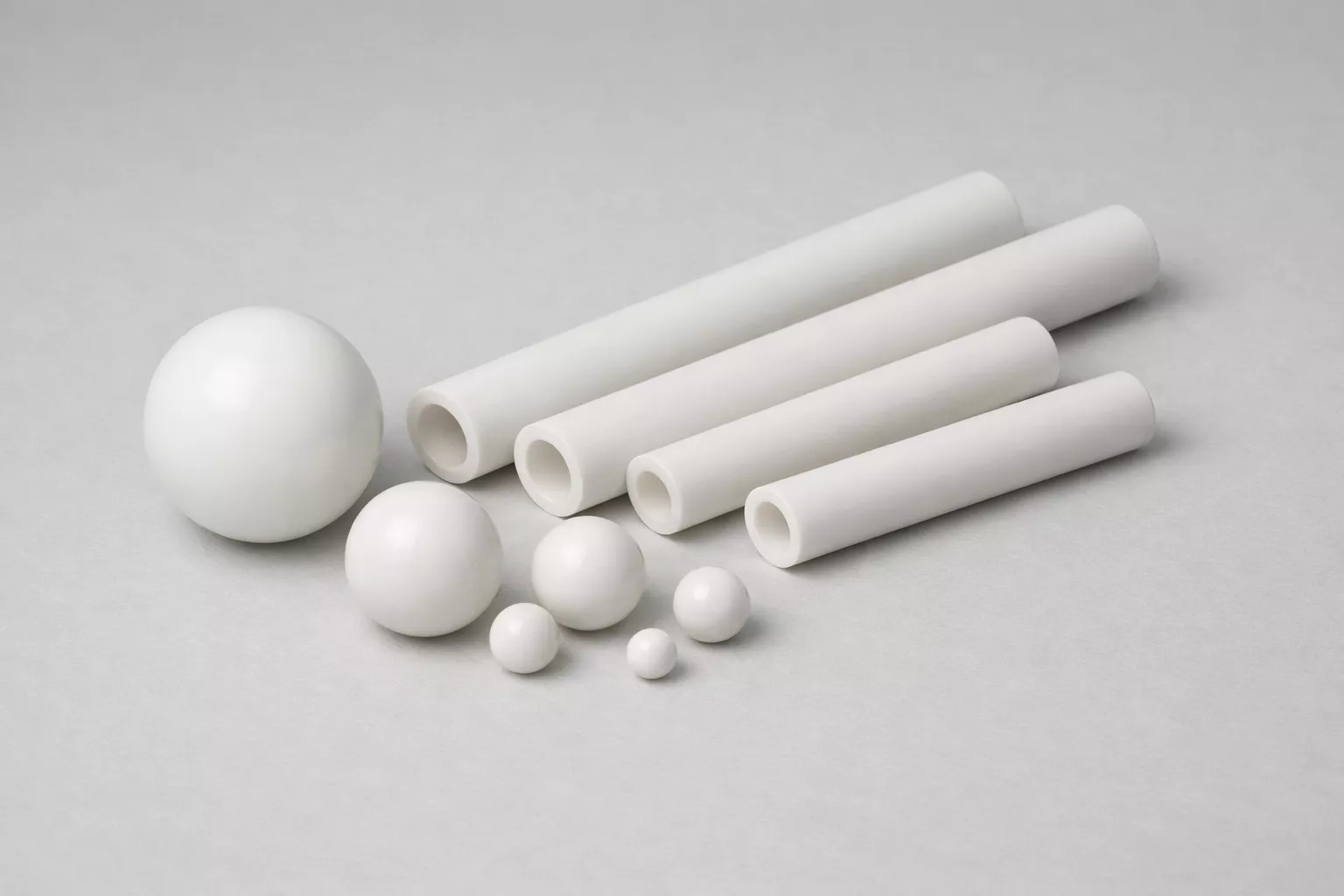

What Is Zirconia Ceramic Used For

High-performance engineering systems often fail at the material–component interface; therefore, advanced ceramics increasingly define reliability limits in real industrial equipment. Zirconia ceramic occupies a unique

Zirconia Ceramic Evolution From Mineral Discovery to Industrial Dominance

Ceramic components can fail abruptly under heat and stress; consequently, zirconia demanded decades of scientific corrections before dependable service became possible. Zirconia ceramics progressed from

Zirconia Ceramic Material Performance in High Duty Industrial Components

High-duty industrial systems frequently fail when conventional materials reach mechanical, thermal, or chemical limits. Consequently, zirconia ceramic material emerges where durability, predictability, and damage tolerance